with innovative and patented auto-feeding system

The new ANTARES splitting machine has been designed

to simplify the problems due to the lack of

skilled and expert operators normally required for this

particularly onerous operation.

The machine can be fed by a belt which brings the

hides to the introduction system: it will then be the innovative

system (patented) which will automatically

convey and spread the hide presenting it at the splitting

point.

The most interesting and productive use is to put the ANTARES splitting machine in line with the fleshing machine through a belt, thus obtaining a constant production flow without downtime.

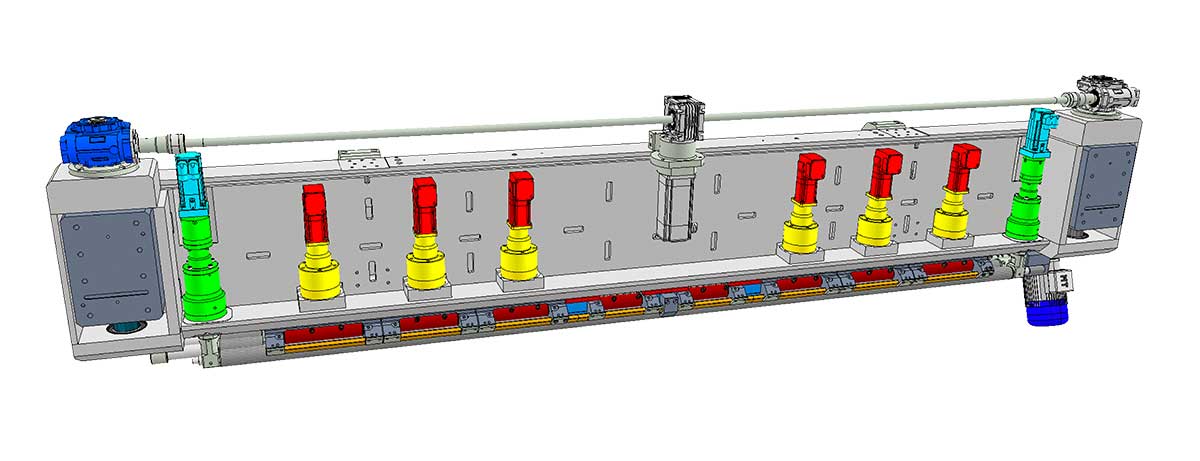

Feeding system

Innovative system (patented) works without scrapers, rings-roller and rubber cylinder.. The new patent provides for an inflatable hose with a special design that allows the split (even if very thin) to come out without any hitches which, in the traditional version, are found between the rings roller and the rings-roller supports. By increasing or decreasing the air pressure in the inflatable hose it is possible to adapt the machine to any leather to be divided , both light and heavy.

Automatic feeding system , patented.

belt, the operators only have to check that they are centered and stretched out, the rest is done automatically by Antares. The system is made up of three upper spreading cylinders and three lower rubberized support cylinders which direct the well-stretched leather towards the gauge roller and the blade. The leather will arrive well stretched to the gauge roller assuring an excellent thickness results. As already mentioned, the machine is designed to also be placed in line with the fleshing machine. An excellent combination is a line with ANTARES and the Mosconi back to back automatic fleshing system.

The head is equipped with independent gauge roller

counter-roller supports.

Individual movement of each counter-roller is possible

via centesimal brushless motors to profile the gauge

roller.

This system allows accurate thickness precision results

as the gauge roller adapts to any type of leather

to be split.

The equipment of a pressurized washing system of the rollers and jaw blade, programmable via PLC, guarantees a considerable saving of water. Programmable automatic greasing device. ANTARES can be compared to all effects to a CNC machine. Customizable programs according to the hides can be memorized.

Control panel with touch screen

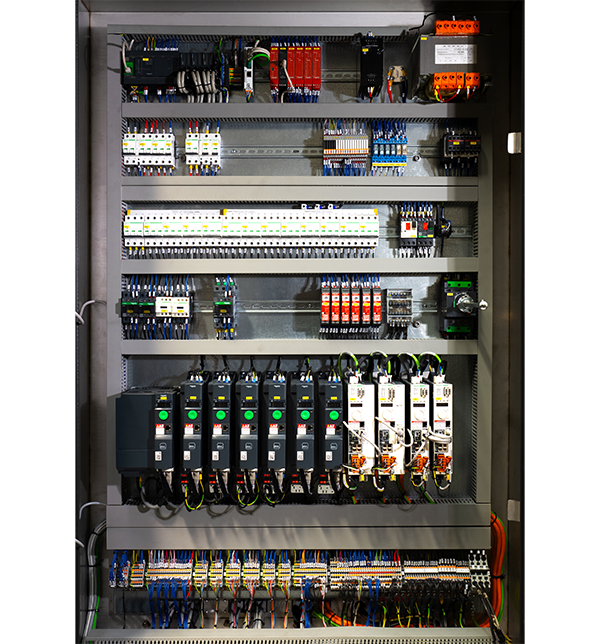

Electrical panel with drives for brushless motors

When recalled, it will reset the machine automatically to the programmed settings. This allows you to quickly adapt the setting according to the work requirements. The movements of each single part of the machine are displayed in real time on the touch screen.

The data shown are indicative and may undergo changes.

| ANTARES | 3000 | 3200 | ||

|---|---|---|---|---|

| Working width | mm | 3000 | 3200 | |

| Lenght | mm | 6560 | 6760 | |

| Depth | mm | 2880 | 2880 | |

| Height | mm | 2000 | 2000 | |

| Maximum installed power | kW | 40 | 40 | |

| Net weight | kg | 12400 | 12850 |