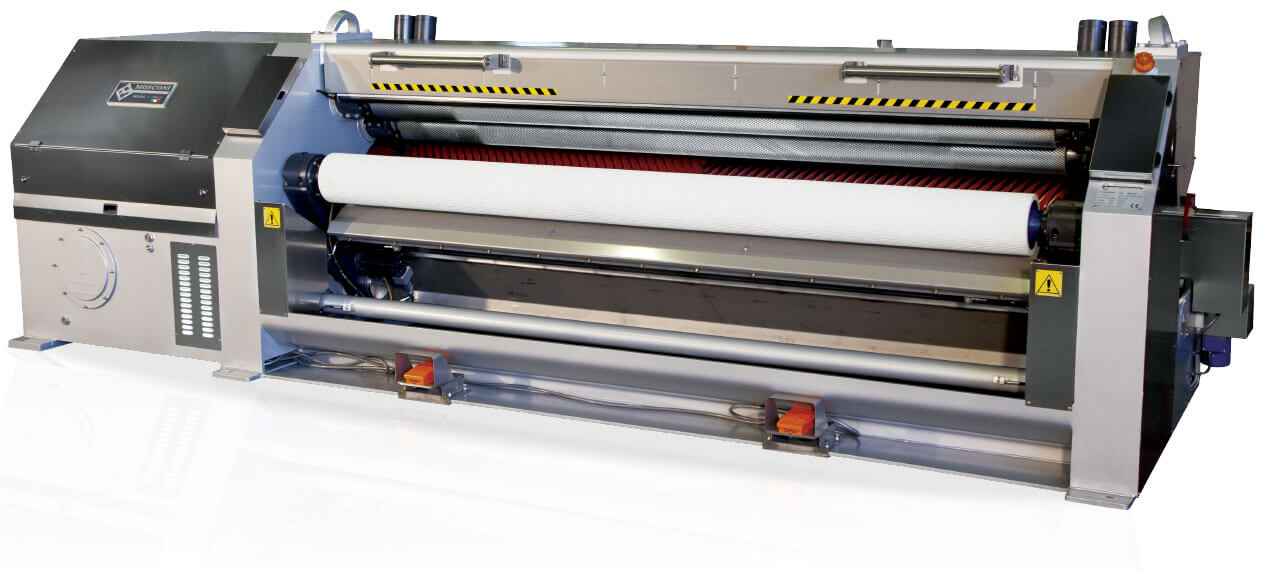

The front linkage has a completely closed shoulder and stainless steel protective cover to guarantee the operator’s safety. The control panels are protected and easy to understand. Mosconi spa has manufactured the new SM XII fleshing machine model with innovative technical solutions, enhancing the robustness and ensuring easy use and maintenance (which varies according to the environment in which the machine is used). The heat-treated monobloc structure, the large cylinder diameters and the precise choice of components allow lime-split and hair on hides to be processed even in extremely harsh conditions, and to obtain accurate fleshing and good trimming of the hide’s edges.

The SM XII fleshing machine has a full stainless-steel cover.

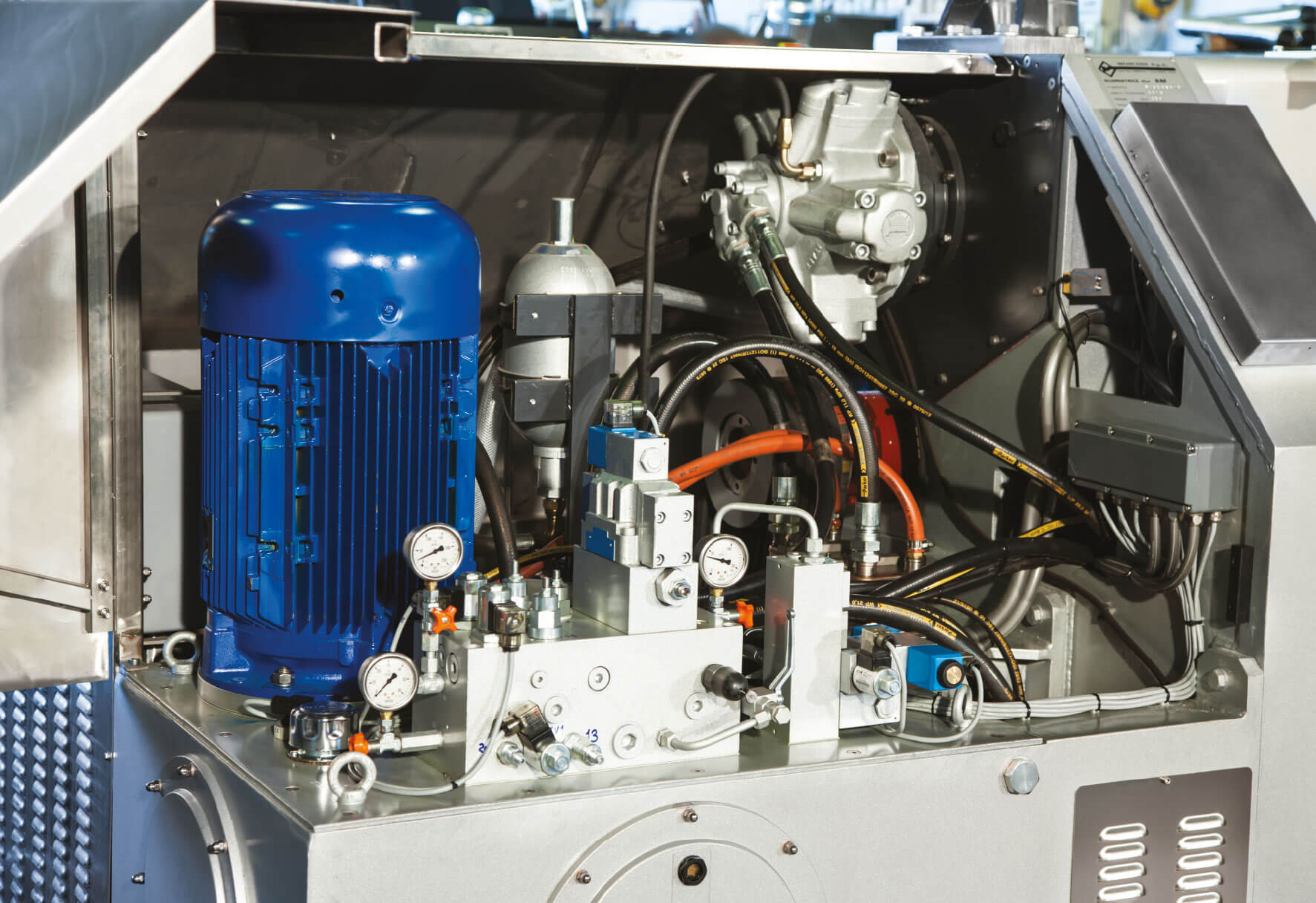

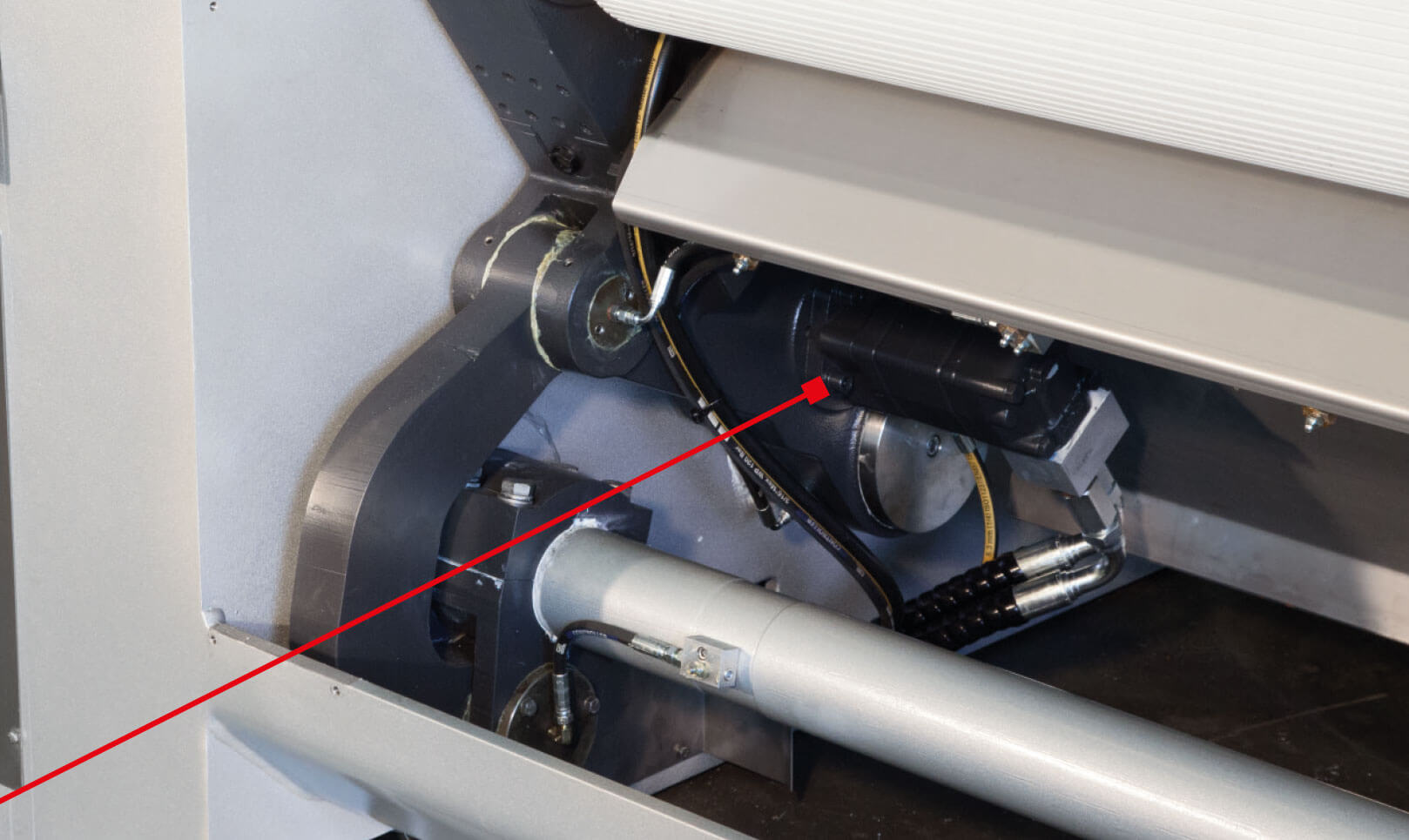

It has a timed automatic opening to reduce downtime. The safety barrier promptly reopens the operating cylinders. To ensure the operator’s safety, Mosconi spa has designed the SM XII fleshing machine with a photocell that stops the machine closing in the presence of an obstacle. In the event of a power cut or hydraulic pump failure, the machine opens automatically. The hydraulic power unit and the electric panel are built-in to the structure to minimise the overall dimensions of the machine. Lubrication takes place with centralised greasing points.

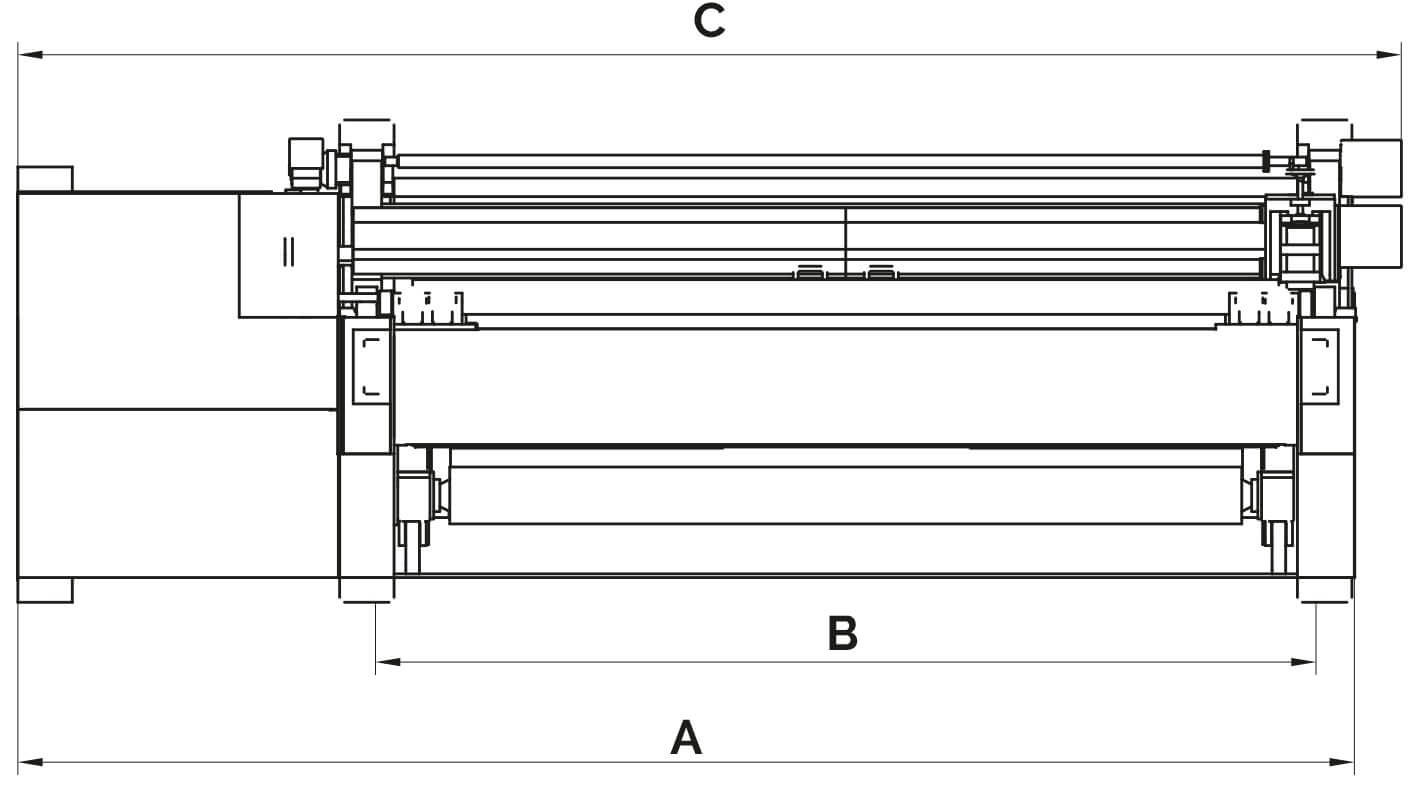

| SMXII | |||

|---|---|---|---|

| Working width | mm | 2700 | 3200 |

| Length [A] | mm | 4900 | 5400 |

| Width [B] | mm | 3300 | 3800 |

| Length [C] | mm | 5120 | 5620 |

| Maximum installed power - 50 Hz | kW | 78 | 78 |

| Maximum installed power - 60 Hz | kW | 94 | 94 |

| Net weight | kg | 11000 | 11000 |

Upon request, the company equips the SM XII fleshing machine with:

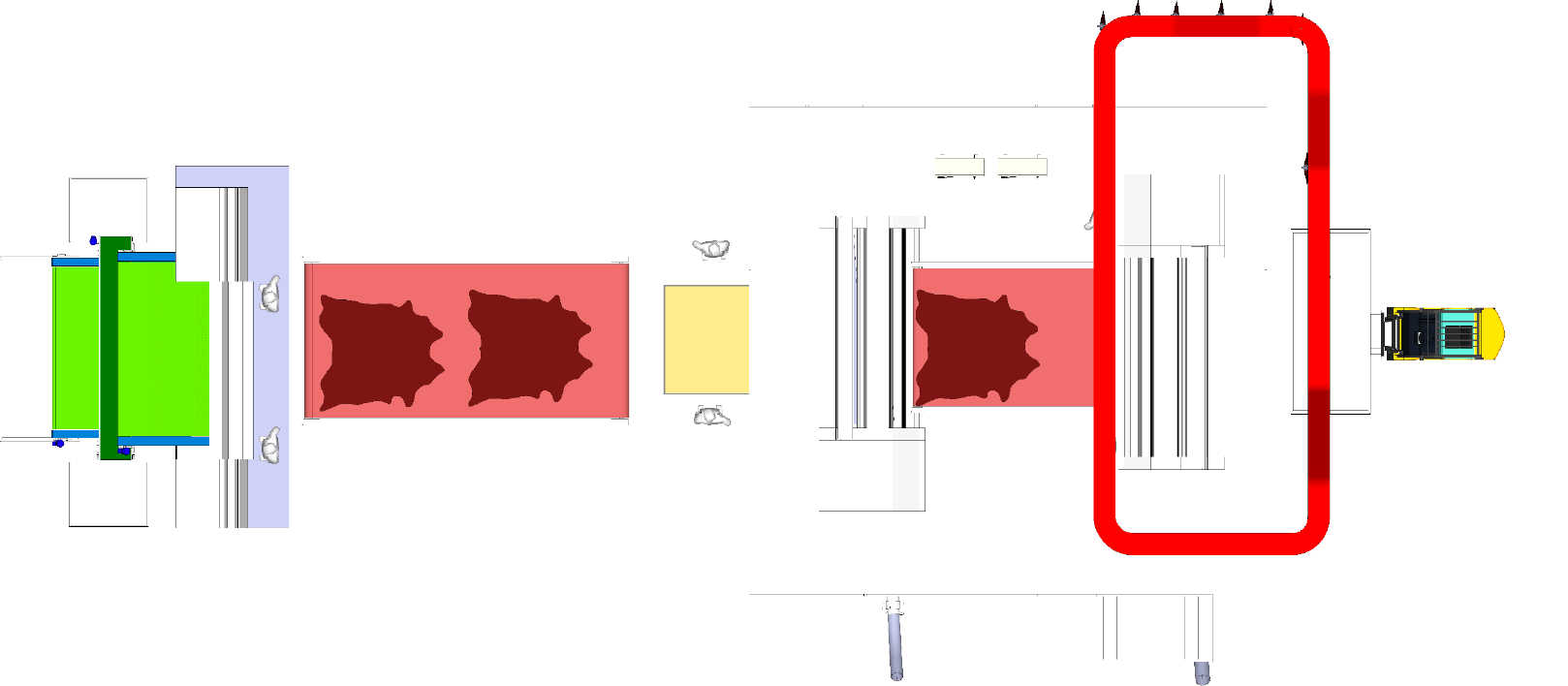

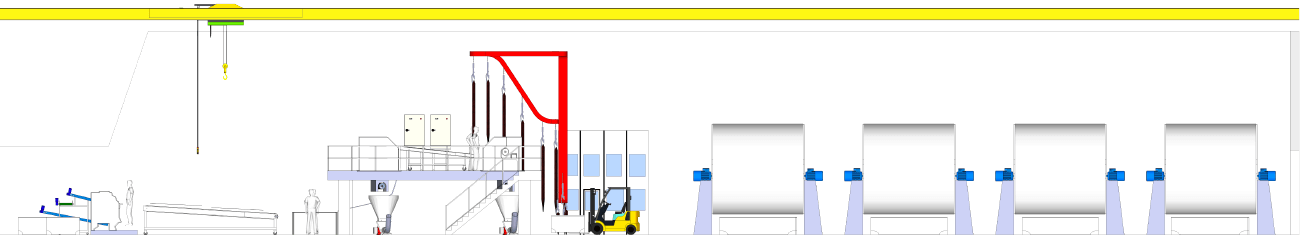

Back to back technology, which is two combined units, represents various advantages for the tannery and fleshing hides, including:

In fact, thanks to this system, if one machine is not operating, it is possible to flesh with the other without stopping production.

1

The two operators on the fleshing machine use the first machine conventionally, with the only difference that, after having loaded the hide into the machine and fleshed the first part, they extract it to send it to the second machine on a conveyor belt.

2

The hide arrives at the second machine with the unfleshed part in front, ready to be inserted. The presence of the hide is detected by the automatic system.

3

In this second work station, the outfeed hide is not collected, but left to fall onto the slide below, where it is trimmed and sent to the subsequent processing.

Would you like to have further information on the Mosconi SM XII machine? Contact the company: our technicians are at your disposal.