To meet the broad market and the various productions, the company has produced two versions of the Aster shaving machine: 1800-2400 and 2500-3200. Mosconi spa has particularly focused on the design and production of the beam and fixed blade cylinder. The new technology is joined by the essentiality of the controls and by the innovative functions, designed for the simple and immediate use of the machine by the tannery operators. An example is the new Aster equipment: a modern touch screen control panel to view the interactive pages. All the components have been designed to guarantee the best result in each shaving phase.

SHAVING MACHINE

With a working width from 1800 to 2400 millimetres, the new Aster shaving machine model has been made in a single heat-treated stabilised monobloc, whose structure does not become deformed in time: an advantage guaranteed by the manufacturing reliability of Mosconi.

You may also be interested in Mosconi shaving machine 2500-3200 Mosconi: click here for further details!

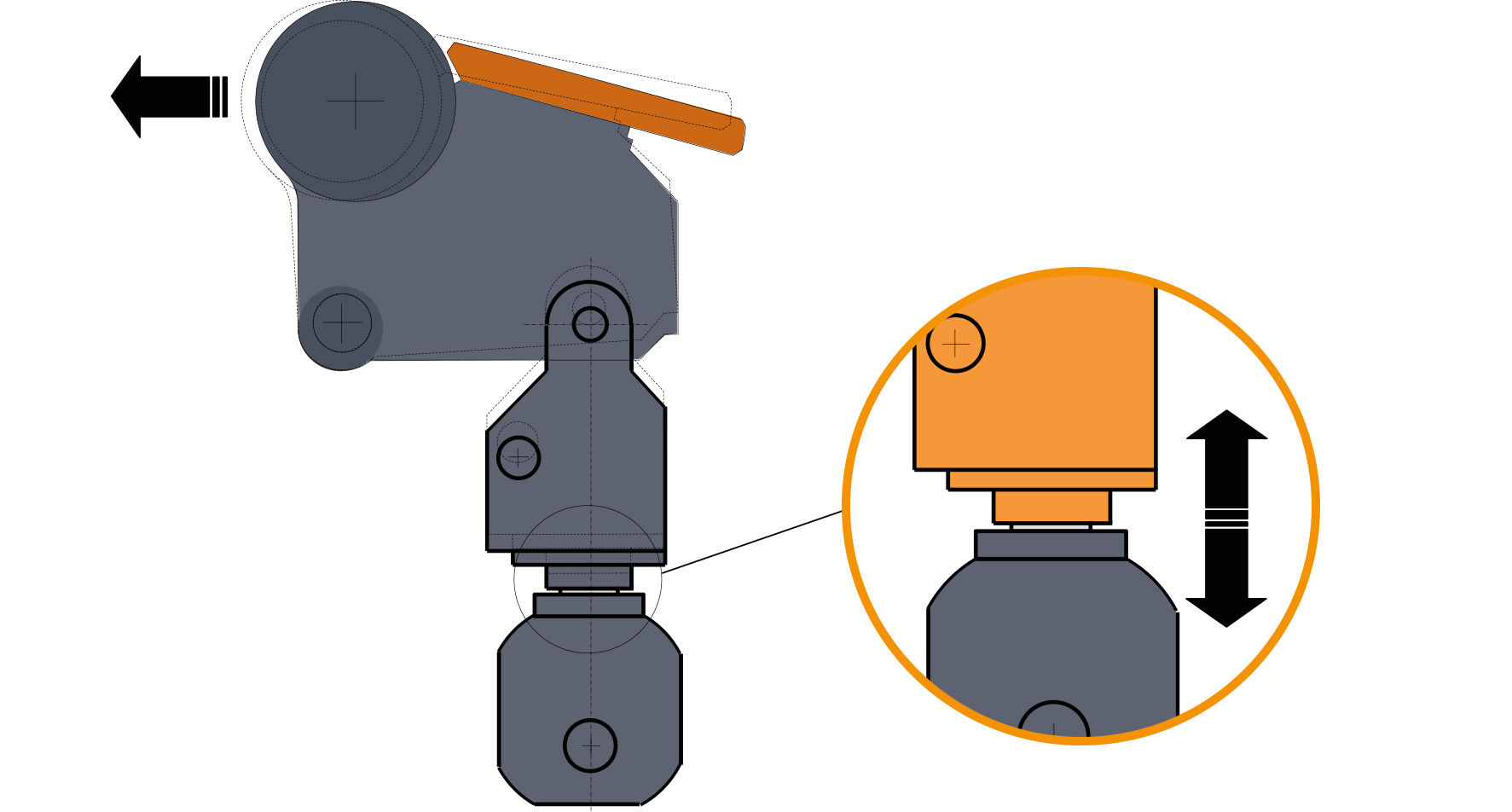

The thickness (increases, decreases and fine adjusting) has been chosen with a centesimal variation.

The working speed is from 0 to 50 metres a minute on the infeed and 70 metres a minute in the outfeed.

Other features are:

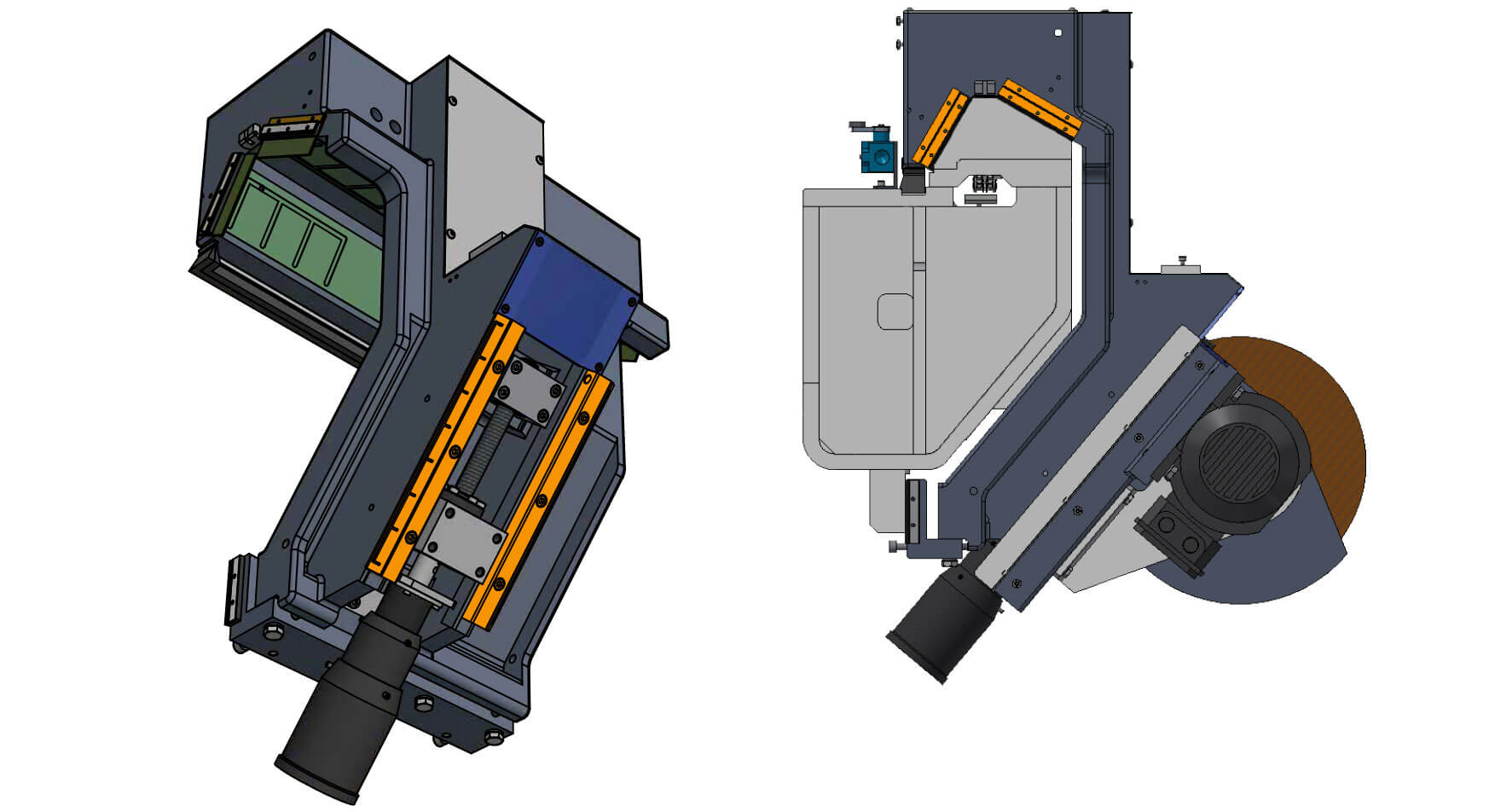

The Aster model also has support bases of the grinding carriage with Turcite insertion, sliding guides for the grinder carriage made of cemented and ground steel, electric drive for the grinder movement and “detach-attach” control.

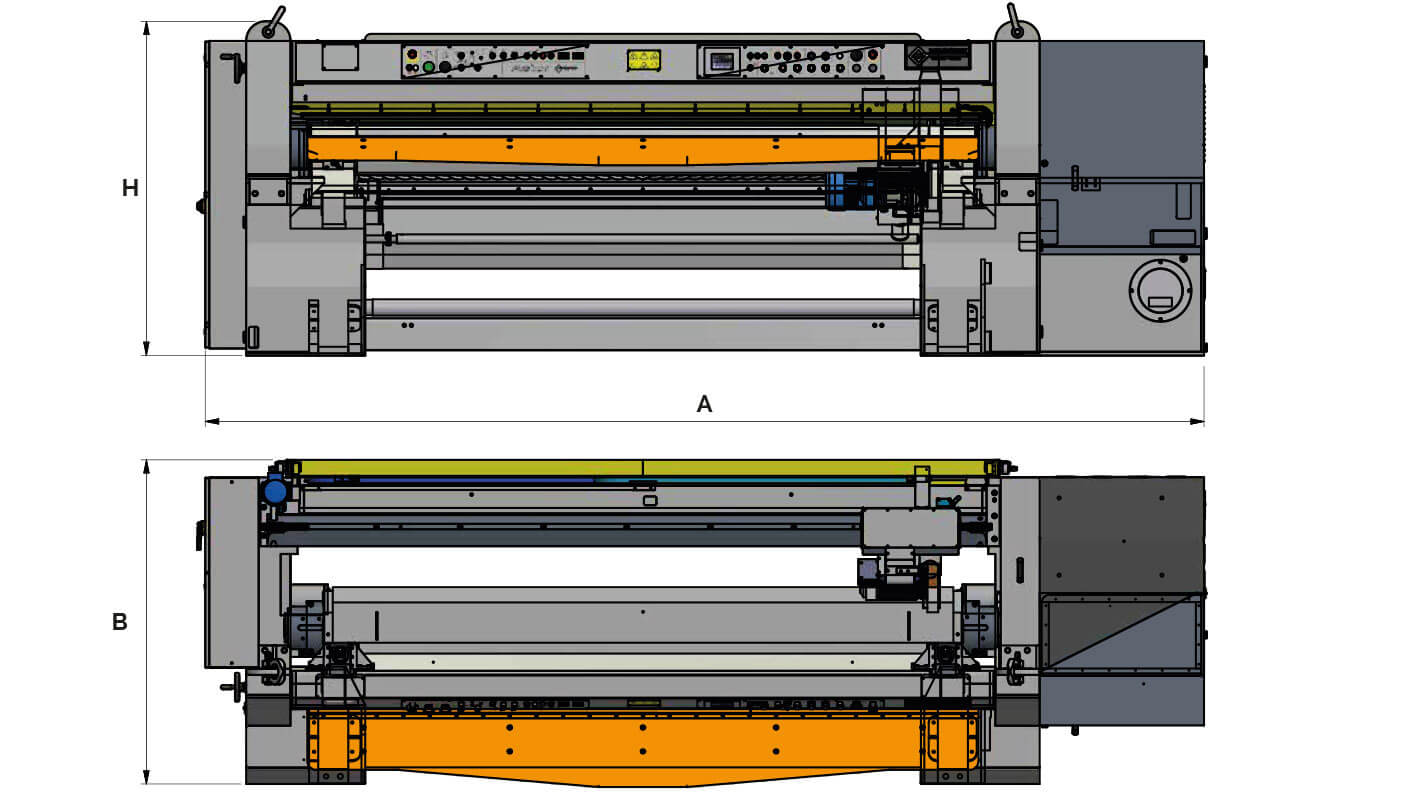

| ASTER 1800-2400 | 1800 | 1900 | 2200 | 2400 | |

|---|---|---|---|---|---|

| Working width | mm | 1800 | 1900 | 2200 | 2400 |

| Length [A] | mm | 4142 | 4242 | 4542 | 4742 |

| Width [B] | mm | 1702 | 1702 | 1702 | 1702 |

| Height [H] | mm | 1740 | 1740 | 1740 | 1740 |

| Maximum installed power - 50 Hz | kW | 64 | 64 | 64 | 64 |

| Maximum installed power - 60 Hz | kW | 72 | 72 | 72 | 72 |

| Net weight | kg | 6800 | 7000 | 7300 | 7500 |

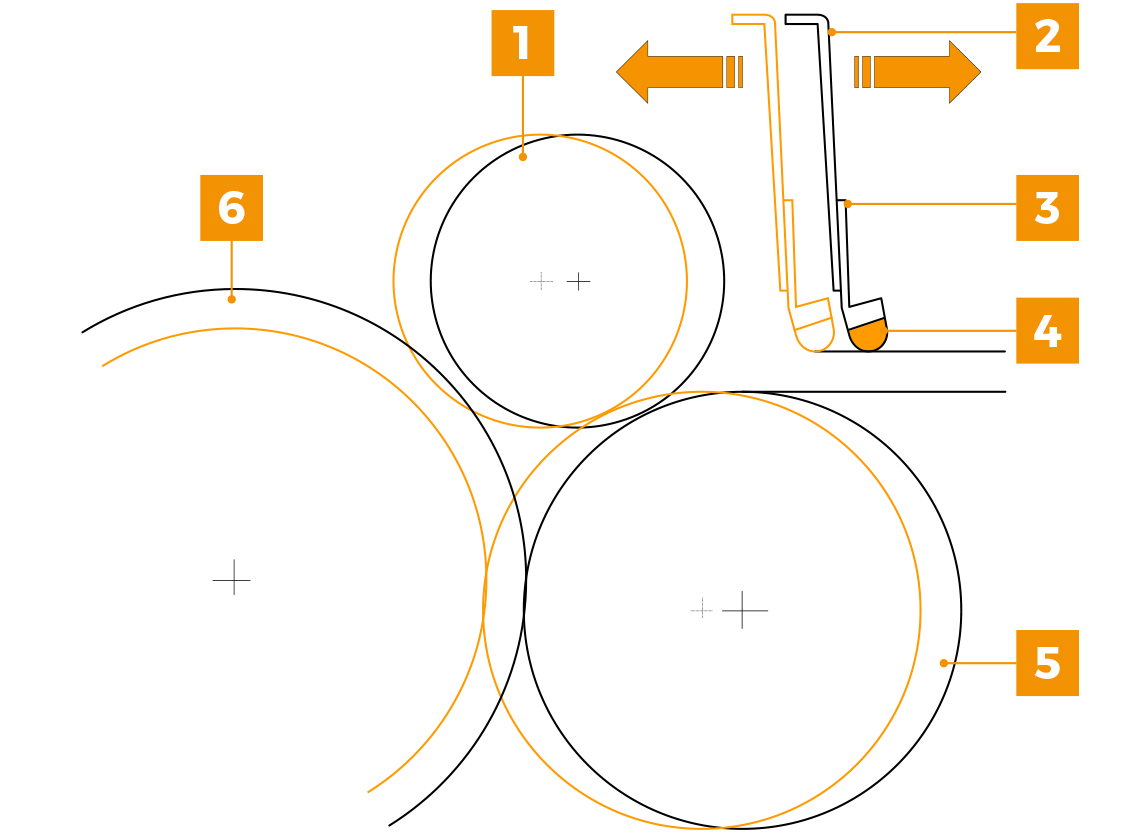

The choice of using fixed blade beam and cylinder has allowed us to create an original patented solution to control the grip pressure of the rubber-coated roller. The supports move on guides that allow the distance set between the rubber-coated cylinder, the blades and the working pressure to remain unchanged, until they are completely worn. This ensures the constant grip pressure, damage reduction on the front tips and, above all, allows a very high degree of safety for the operator, as the protective barrier moves in complete synchrony.

Other details of the new Aster shaving machine:

For a quote o further information on the Aster model shaving machine, contact the company!